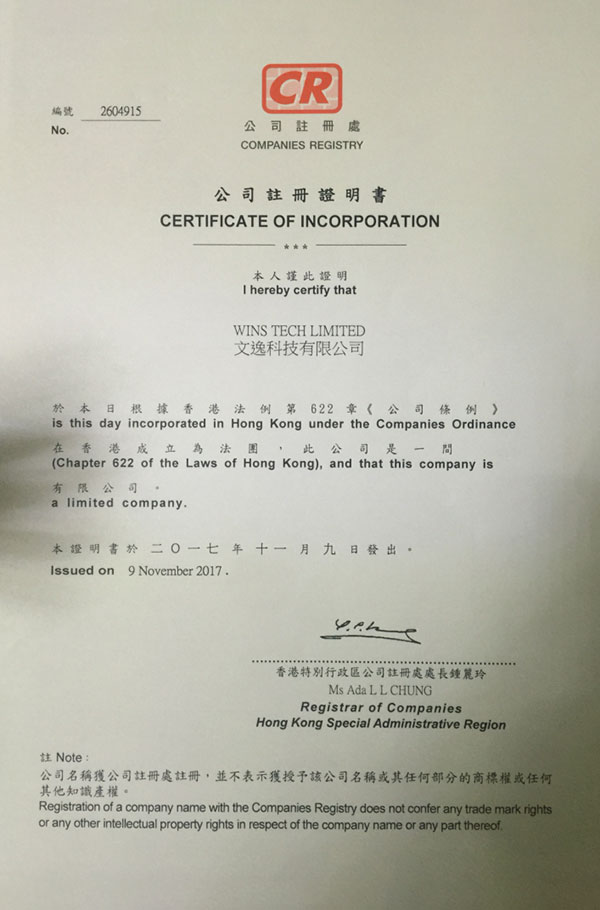

Wins Tech Limited, founded on 2012 which professional in provide custom high

precision CNC machining service, processing with supplied drawings

or samples.

We accept all kinds of material processing service, they are

included plastic , aluminum alloy, brass , stainless steel and so

on, OEM and ODM are acceptable.

Which industries does Wins tech limited serve?

CNC Machining Services is serving Automotive, Aviation,Consumer

Electronics, Computer peripheral, Communication, Home Appliances,

Industrial Application, Machinery, Medical, Office Equipment,

Robots, Storage, Toy and much more. Each month, we delivered

millions of parts to our customers both in domestic and overseas.

What is the workable machining materials of Wins tech limited ?

Wins tech limited can CNC machine metal and plastics parts or

components for you. Machinable materials including but not limited

to Aluminum, Brass, Copper, Stainless Steel. Such as AL2014,

AL2017, AL5052, AL6061, AL6082, AL7075, SUS201,SUS303, SUS304,

SUS316, 316L, 17-4PH, LY12, 65Mn, Cr12, 40CrMo, AL6063 ,

ST12.03,SS2331, AISI12L14, Y15, 45#, Q275, ABS, Bakelite ,POM, PC,

PEEK, Nylon, Teflon and Acrylic.

Wins tech limited have more than 14 years manufacturing experience, 70 more skillful

operators, 10 more rich experience professional engineers, which

ensure products good quality, high productivity, and R&D

capability.

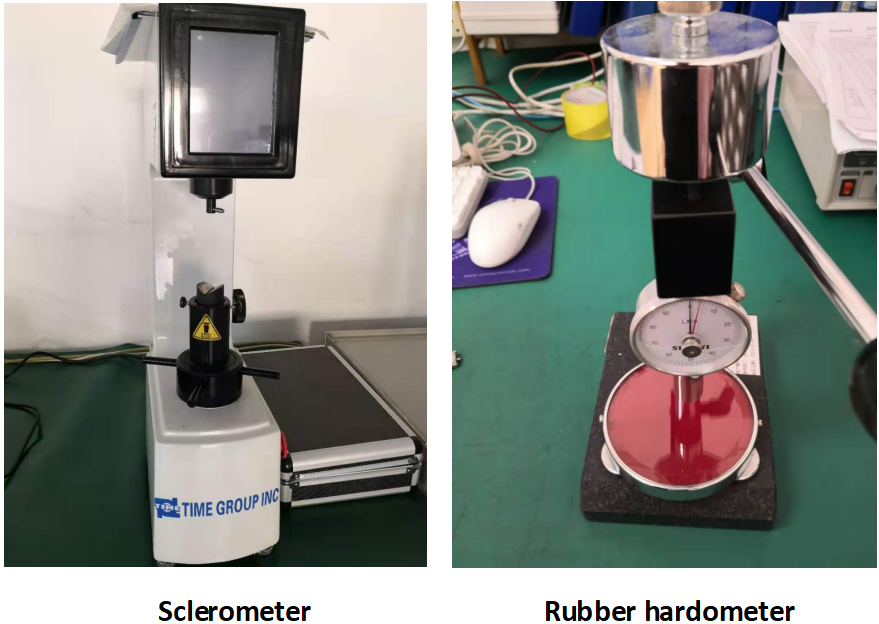

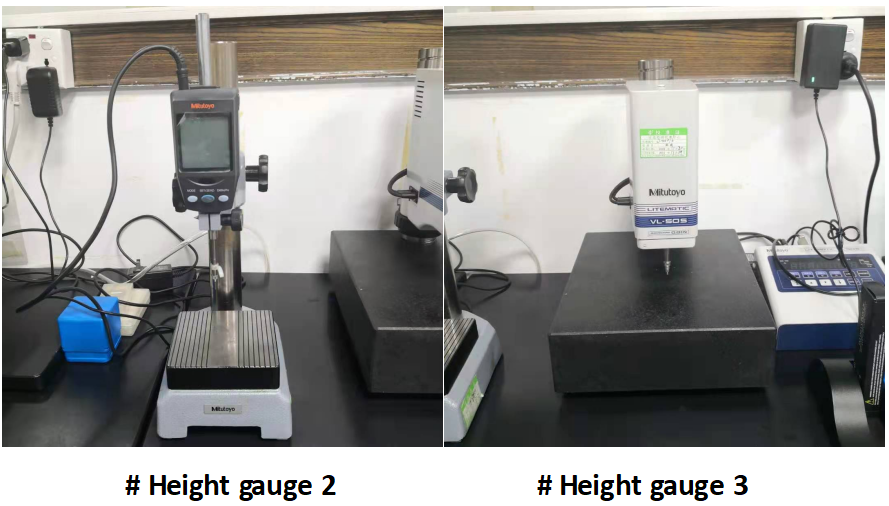

Wins tech limited is equipped with state-of-the-art high precision CNC machining

equipment and testing equipment including 3 axis, 4 axis and 5 axis

CNC machining centers, CNC lathes, Swiss CNC Machining Centers,

precision turning centers, precision grinders, slow wire EDM

cutters, precision stamping presses, 2D optical measuring

instruments, 3D coordinate measuring machines, height meters,

microscopes, roughometres, and metal material detectors, giving us

extensive precision CNC machining manufacturing and high quality

control capability.

WINS TECH LIMITED located in Shenzhen Guangdong province China , own 4

production lines, factory area 3000 square meters which monthly

production capacity up to 1000K.

Beside, we have 7 rich experience structure engineers and 3 design

engineers, have the ability to completely satisfy client’s

customization requirements.

Wins tech limited guarantees the quality of your machined parts with our ISO

9001:2015, ISO 14001, and IATF16949:2016 certified quality

management system, ITAR registration, and options to add

inspections, hardware traceability, material certifications, and

CoCs. We accept technical drawings and have support teams to ensure

you get quality CNC machined parts on time.

Factory location:

BLK A UNIT 3 FU KANG YUAN NO 104 LONG CHENG AVENUE CITY CENTRE LONG

GANG SHENZHEN

ZIP CODE: 518172

We warmly welcome clients from all over the world to come to our

factory for visit and cooperation!