Prototype Custom CNC High Precision Milling Turning Services

Wins tech limited Always Offer Our Customers Competitive Product Price, Well

Controlled Quality System, Always On-Time Delivery (Prototypes

Within 1 Week, Samples Can be Expedited Within 10 Days, Mass

Product Delivery (MOQ) Lead Time Can Always be Less Than 25 Days. )

and Circumspect Communication and Service to Customers, We Have Won

The Heart For Every Customer Who Has Ever Did Business With Us. Our

Products are Widely Sold In Domestic Market, North America and

European countries.

Whether you have never brought your idea to life or you are already

in the process of producing at high volumes, we are a one-stop-shop

for your machining needs. Absolute will manage your entire project,

meet your timelines, and ship product to specification.

Our wide knowledge of engineering materials allows us to assist you

in the selection of the best material for your project. Absolute

works closely with material suppliers to help you determine the

most effective material for your product, at the right price.

The key advantages and disadvantages of CNC technology are summarize below:

- CNC machining offers excellent accuracy and repeatability and can

produce parts with very tight tolerances, making it ideal for

high-end applications.

- CNC materials have excellent and fully-isotropic physical

properties and are suitable for most engineering applications.

- CNC is the most cost-effective manufacturing process for producing

low-to-medium numbers of metal parts (from one-off prototypes, up

to 50000 units)

- Due to the subtractive nature of CNC machining, specific geometries

are either very costly or impossible to manufacture.

- The start-up cost of CNC machining is high compared to 3D printing,

so CNC is less suited for low-cost prototyping (for example,

comparing metal and plastic).

The lead times of CNC machining (10 days) are longer than the lead

times of 3D printing (2-5 days), as CNC machines are not as widely

available since they require expert knowledge to operate.

Customer Ever Said:

. I want to say that your products are very good. Thank you for all

your suggestion, also good after sales service. -- Adela

. We trust the quality of your products. It always the best. Keep

this going, and we will establish a long-term trade relationship

with you. -- Charlie Bingham

. It has been more than 2 years we worked together, we are very

happy working with them.--MICROTEX INC.

. Their products are very good,I trust this company.--RICHARD

ENGSTROM

Advantages:

Professional Research and Design Team, Processes All Necessary

Equipments:

Extrusion Machine: 2 Sets; CNC Machine: 20 Sets (Maximum working

platform: 1600*80), Drill/threading machining: 25 Machines

- Strict Quality Control in Each Process and Finish Product Quality

Control

- Short Delivery Lead Time: 15-30 Days

- Optional For OEM or ODM

- Comprehensive After-Sale Service, Quick Responses For Daily

Communication

WINS TECH LIMITED EQUIPMENT LIST |

|

|

|

| Item | Classes | Equipment | Brand | Quantity | Unit | Service time | on state | Notes |

| 1 | General-purpose machine tool | Miller | Jaguard | 3 | set | 2 years | under normal service conditions | |

| 2 | Jaguard | 3 | set | 2 years | under normal service conditions | |

| 3 | Foshan machine | 1 | set | 2 years | under normal service conditions | |

| 4 | Turning-lathe | Guangzhou Nanfang | 1 | set | 2 years | under normal service conditions | 6140D |

| 5 | Digital controlled lathe | CNC lathe | Taihe | 6 | set | 2 years | under normal service conditions | 46 line cutter machine |

| 6 | 4 axis precision automatic lathe | SUPVAN | 3 | set | 2 years | under normal service conditions | |

| 7 | 5 axis precision automatic lathe | NONO | 3 | set | 2 years | under normal service conditions | |

| 8 | Digital controlled lathe | CNC machining center | | 4 | set | 0.1 year | under normal service conditions | 850H |

| 9 | CNC machining center | Xin Tenghui | 1 | set | 2 years | under normal service conditions | 1280H |

| 10 | CNC machining center | Xin Tenghui | 1 | set | 2 years | under normal service conditions | 750H |

| 11 | CNC machining center | J-Y CNC | 3 | set | 2 years | under normal service conditions | 650H |

| 12 | CNC machining center | DeMarco | 2 | set | 1 year | under normal service conditions | 2150H |

| 13 | CNC machining center | | 2 | set | 2 years | under normal service conditions | 46 line cutter machine |

| 14 | CNC lathe | Taihe | 8 | set | 1 year | under normal service conditions | 46H |

| 15 | Cutter tower turning milling compound machine | | 1 | set | 0.5 year | under normal service conditions | 46H |

| 16 | CNC turning milling compound machine | Taihe | 3 | set | 1 year | under normal service conditions | 325-355 |

| 17 | Line cutting equipment | wedm-ls | SODICK | 3 | set | 5 years | under normal service conditions | 500H |

| 18 | wedm-hs | Changan | 2 | set | 1 year | under normal service conditions | 540H |

| 19 | wedm-hs | Taizhou | 2 | set | 1 year | under normal service conditions | 540H |

| 20 | Auxiliary equipment | hand drilling machine | | 1 | set | 1 year | under normal service conditions | |

| 21 | perforating machine | | 1 | set | 1 year | under normal service conditions | |

| 22 | tapping machine | | 2 | set | 1 year | under normal service conditions | |

| 23 | chamfering machine | | 2 | set | 1 year | under normal service conditions | |

| 24 | sharpener | | 2 | set | 1 year | under normal service conditions | |

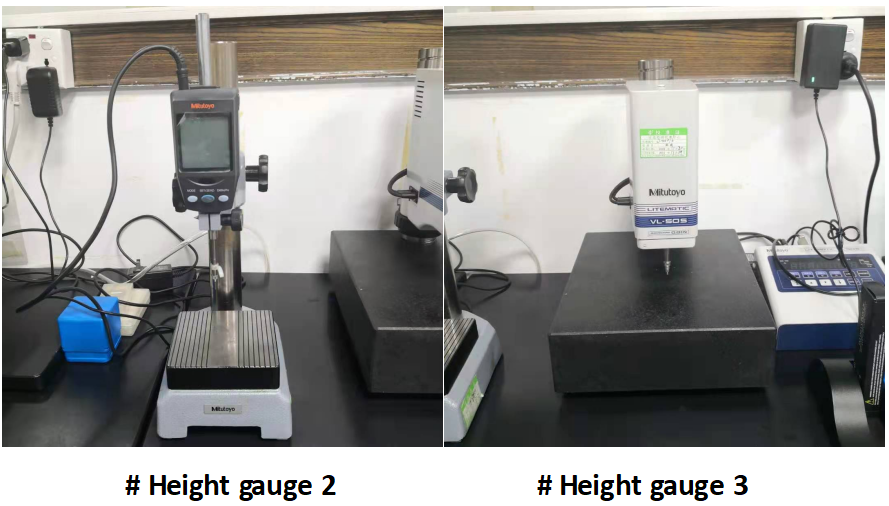

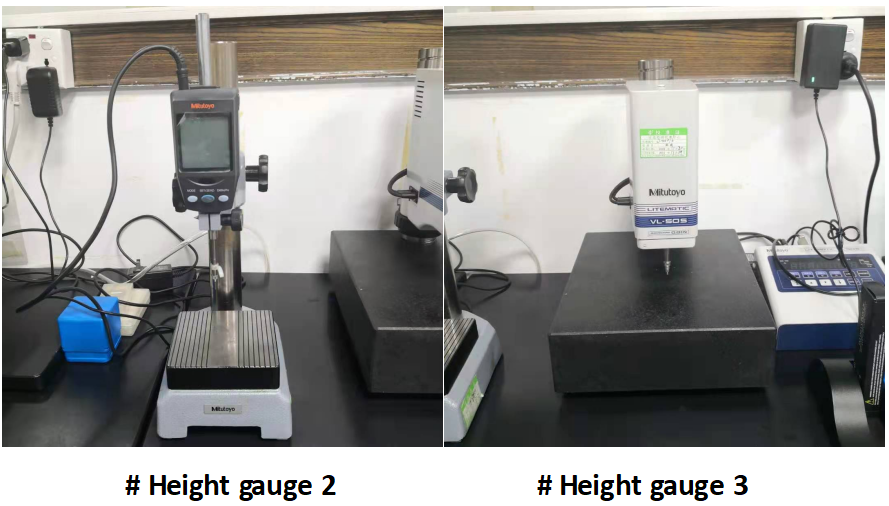

| 25 | Inspection equipment | height gauge | | 3 | set | 1 year | under normal service conditions | |

| 26 | Two dimensional image measuring instrument (YVM) | | 1 | set | 1 year | under normal service conditions | |

| 27 | Three dimensional detection | | 1 | set | 1 year | under normal service conditions | |

| 28 | Surface roughness tester | | 2 | set | 1 year | under normal service conditions | |

| 29 | tensile machine | | 2 | set | 1 year | under normal service conditions | |

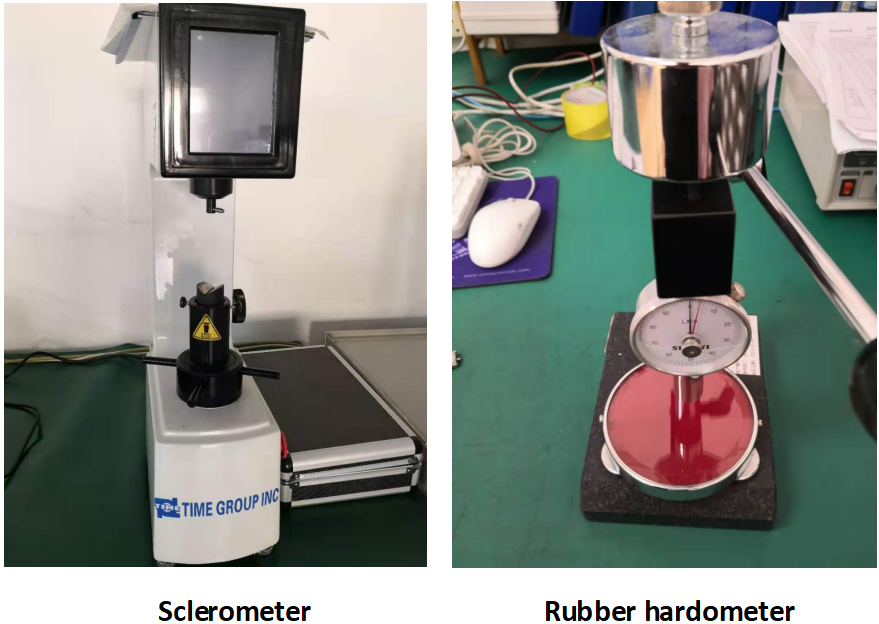

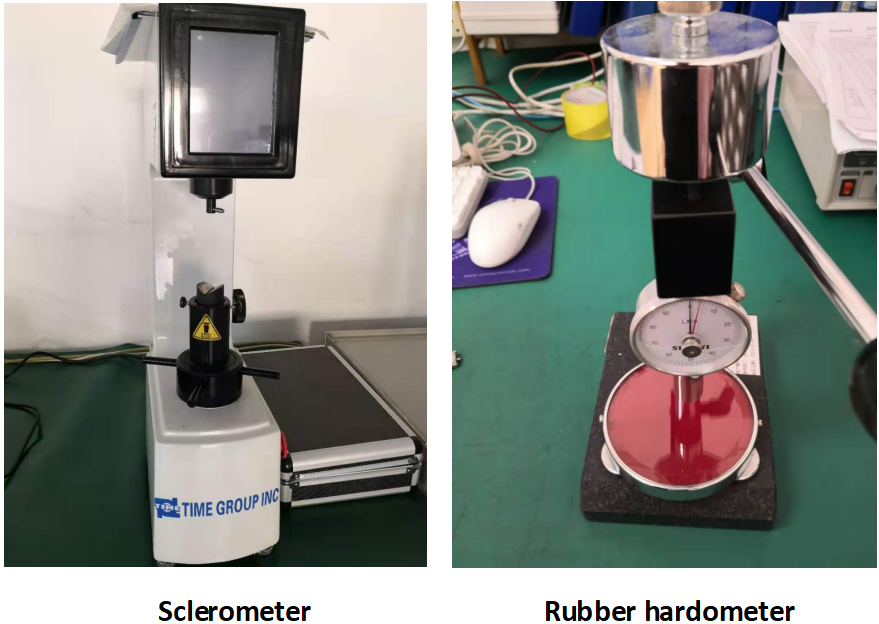

| 30 | sclerometer | | 2 | set | 1 year | under normal service conditions | |

| 31 | microscope | | 1 | set | 1 year | under normal service conditions | |

| 32 | True roundness detector | | 1 | set | 1 year | under normal service conditions | |

FAQ:

» Sample & Mold

Q : Can i have a trial order or samples only for several pieces?

A : As the product is customized and need to be produced, we will

charge sample cost, but if the sample is unqualified, the sample

will be free or after you placed mass orders, we will refund the

sample cost.

Q : Can you open mold for us to manufacture new product?

A : Yes! if the quantity is big, our company can afford part of the

mold cost.

» Delivery time & after-sales service

Q : Can you provide after-sales services?

A : Generally it is 20 -30 days after the drawing confirmed.

Generally it is 20 -30 days after the drawing confirmed .

Q : Can you open mold for us to manufacture new product?

A : Yes, every defected products will be replaced and the cost be

responsible by us or we will send new ones to customer immediately

if it is urgent. However, it would take some time for the first

production and almost 0 bad feedback from our customers after then

.

» Payment Terms

Q : What is your terms of payment?

A : T/T(For big order, 30-90 days can be acceptable)

» About quotation

Q : How can i get the quotation?

A : Please send us information for quote; drawing, material,

weight, quantity and request, we can accept PDF, ISGS, DWG, STEP

file format.

If you don’t have drawing, please send the sample to us, we can

quote base on your sample too.

Quality inspection:

Zero defect rate target, automatic inspection equipment;

One-stop customized manufacturer accept all kinds of materials;

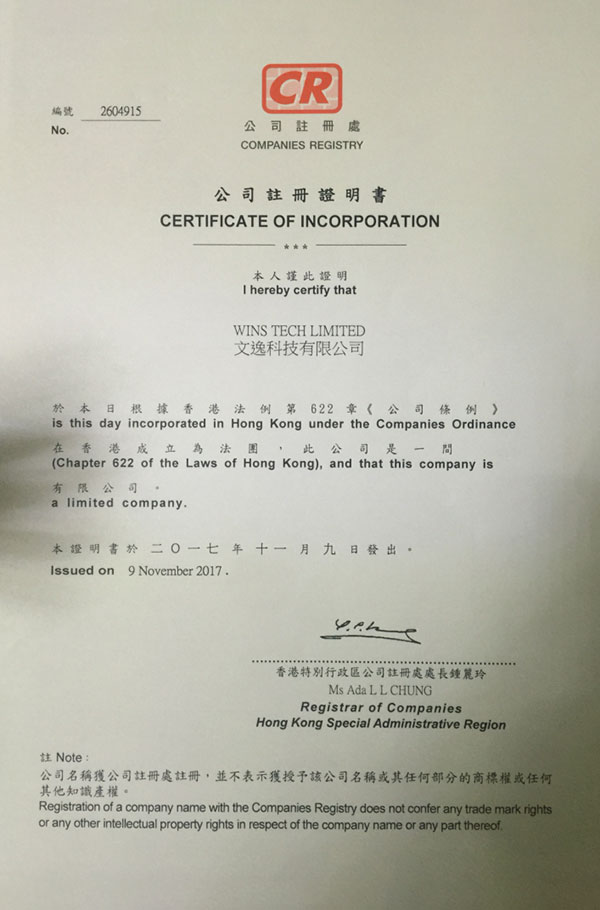

About WINS TECH LIMITED:

· March, 2012: WINS TECH LIMITED Set Up

· October, 2014: ISO9001 Certificate

· September, 2017: WINS TECH LIMITED HongKong branch office Set Up

· December, 2017:start to expand overseas markets

· May, 2019: 2 automatic production lines set up, 4 production lines in total,

factory production capacity over 1 million

· May, 2020: ISO14001 Certificate

· September, 2021: IATF16949 Certificate

· 2022~ : to be continue

Certifications

Wins tech limited guarantees the quality of your machined parts with our ISO

9001:2015, ISO 14001, and IATF16949 certified quality management system, ITAR registration , and

options to add inspections, hardware traceability, material

certifications, and CoCs. We accept technical drawing and have

support teams to ensure you get quality CNC machined parts on time.

High speed fabrication and prototyping!

We accept OEM and ODM, customizable!

We warmly welcome clients from all over the world to come to our

factory for visit and cooperation!